JIW grows bridge inspection business 70x by switching to Skydio

Today we share with you the story of Japan Infrastructure Waymark (JIW), a rapidly growing drone service provider (DSP) that provides bridge and culvert inspections to Japan’s network of approximately 714,000 bridges. After an extensive testing process that evaluated DJI, Parrot, Autel, and Skydio drones, the JIW team chose Skydio, citing the onboard intelligence of Skydio Autonomy as the key enabler for their business model. JIW’s 300+ Skydio drones have transformed their operations, enabling safe flights in complex environments, more precise data capture, and scalable operations. After switching from DJI to Skydio, JIW's inspection business grew 70x in 12 months.

“ “Thanks to Skydio Autonomy, our inspectors can benefit from AI-powered obstacle avoidance, which enables safe flights in the GPS- and magnetometer-denied areas that are prevalent under bridges we inspect. No other drone came close to successfully completing bridge inspection missions in our trials process, and we are thrilled to be able to adopt Skydio’s new technologies.”

Challenge: Manual drones required extensive pilot training and generated low precision inspections

Like bridge inspectors worldwide trying to use manual drones, JIW found the hardware-centric UAS options to be incapable of successfully completing the job. The drones needed to fly in and among bridge trusses to meet JIW’s high precision requirements, but manual drones were incapable of flying stably under these structures, and required extensive pilot training just to prevent the aircraft from crashing, let alone complete an inspection. The resulting risk-averse aerial inspections resulted in low-precision data, even after all the expensive hardware, and an inability to capture data of the underside of the bridge where the most important inspection data needs to be captured.

Pre-drone methods of bridge inspection include climbers and snooper trucks, which are expensive and dangerous, but provide more precise inspection reports than manual drones.

Solution: Skydio Autonomy enables safe operations in complex environments to capture more precise data

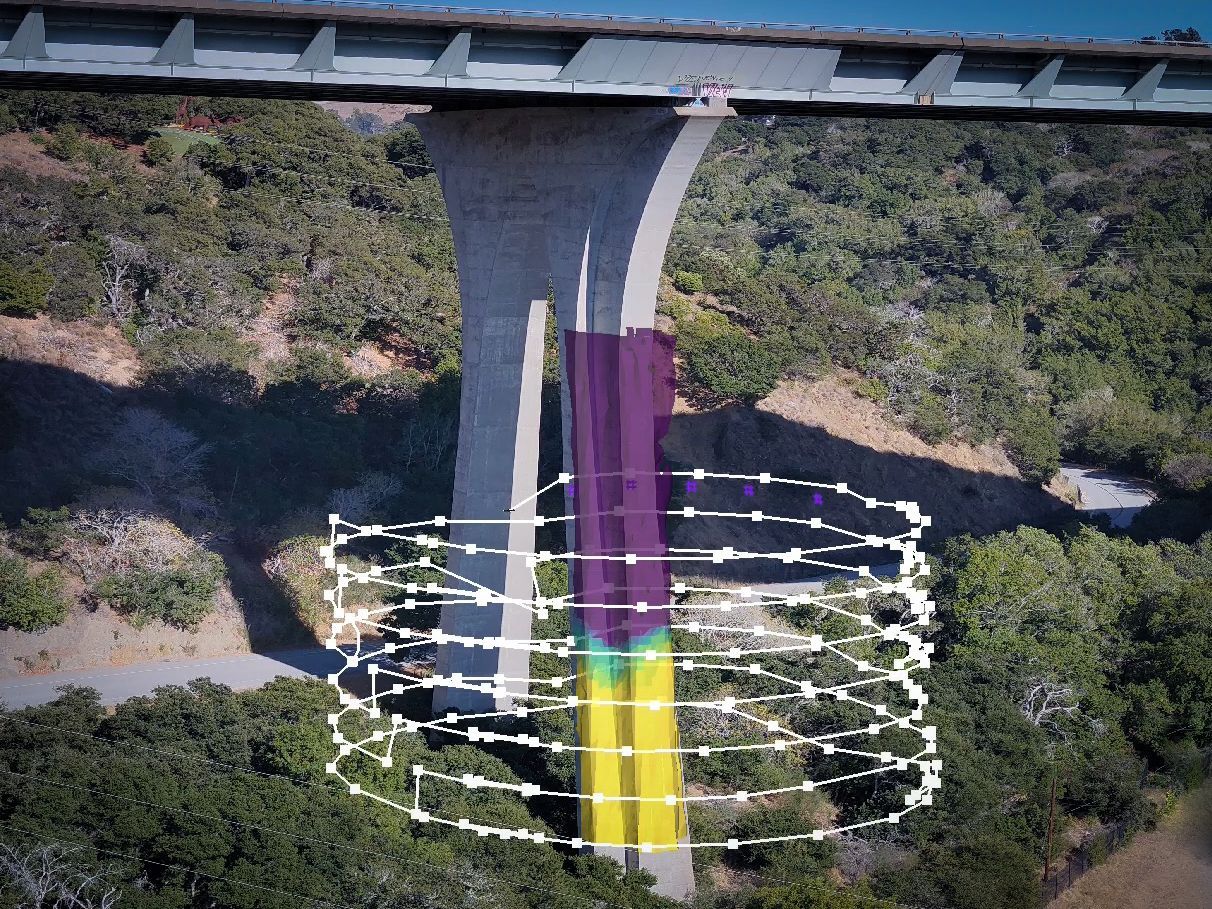

Today, JIW provides the most detailed bridge inspection reports in Japan, and can offer its customers competitive pricing thanks to Skydio. Skydio Autonomy onboard Skydio 2 enables safe operations in complex environments, while Skydio Autonomy Enterprise Foundation (AEF) helps pilots capture more precise images thanks to advanced AI-pilot assist features like Close Proximity Obstacle Avoidance, Precision Mode and Vertical View that allow pilots to get to previously impossible vantage points. The team is contracted to inspect over 700 bridges in 2021 using their fleet of 300+ Skydio 2 aircraft.

Results: JIW’s business has grown 70x and become Japan’s market leader since adopting Skydio Autonomy

Since adopting Skydio over manual drones, JIW has been growing rapidly based on its ability to offer competitive prices, on-board pilots more rapidly, and generate higher quality report outputs. The most notable improvement is the growth of their business, which skyrocketed from 10 bridges inspected in 2019 to a projected 700 bridges in 2021. Additionally, Skydio Autonomy provides 75% cost advantages over pre-drone methods on jobs that manual drones cannot perform, and JIW has on-boarded 68 new pilots in 12 months by lowering the training burden from 100 to 8 hours of flight time. At the end of the day, Skydio enables JIW to inspect more complex bridges with greater precision.

Skydio Autonomy enables inspectors to generate 3D Scans that include the undersides and interior structures of bridges, which are inaccessible to manual drones that cannot fly inside the bridge structure due to their dependence on GPS and magnetometers.

If you want to learn in greater detail how Japan Infrastructure Waymark is generating this incredible value for their own operation and their customers, please come check out the full case study, available for download on Skydio.com. And don’t forget to register for Skydio’s biggest virtual event ever, broadcasting from the U.S. Space & Rocket Center on June 2nd at 9amPT/12pmET.