From books and pictures to digital twins. Making, and capturing history with Skydio 3D Scan.

From my lifelong fascination with history, I know the importance of documentation. It is sad that so much has been lost over the years, from the Library of Alexandria and Buddhas of Bamiyan in Afghanistan, to the Portuguese naval fleet of the 15th Century. While books, drawings, and pictures serve us well, there is a lot left for imagination.

Pictures and books cannot capture every detail of a building or a vehicle, but 3D models generated by drones come very close! With Skydio 3D Scan, drones can autonomously capture a structure’s surface from every angle with complete coverage and ultra-high definition! The images can then be processed in the photogrammetry software (of your choice) to generate 3D models, often referred to as digital twins. These virtual replicas can be used for various purposes: to digitally register a historic building embedded with rich details of art and architecture; to document a car crash for further investigation; to inspect a bridge for maintenance and risk prevention. Today, it is easier than ever to freeze a structure in time, thanks to a simple autonomous drone flight and a whole suite of 3D modeling solutions from companies like Bentley Systems, DroneDeploy, and CapturingReality.

That is why I am so excited to expand on Skydio 3D Scan and showcase some digital twins of our world

Built in 1941 in Frederick MD, this 49-bell carillon is dedicated to local philanthropist Joseph Dill Baker. The tower was captured by Skydio 3D Scan in less than one hour, and processed in Bentley ContextCapture to generate the 3D model you see here.

Inspecting historic buildings can be a difficult task, especially if they are fragile or aged - even the act of physically inspecting can jeopardize the integrity of parts of the structure. With 3D Scan, Skydio can autonomously scan the tower and provide a detailed 3D reconstruction to help inspectors detect even the smallest detail by reviewing the up-close photos, while preserving a digital replica of the scene for historical documentation.

In summary, digital twins created by drones can simplify, speed-up, reduce the cost of documentation and protect the historical buildings from inspection damage. For more details on the model, check out Frederick, MD Bell Tower in our 3D Scan gallery.

Another great example is this ACWR 6910 Train Engine, built in 1997 and remodeled in 2012. Captured in just 38 minutes, with vibrant colors and fine motor details, this model will be recorded, catalogued and referenced for generations. No question, this expertly maintained engine has many more years of service, but this model gives engineers a reference point to ensure the vehicle is kept in its current condition as long as possible. When the vehicle retires, a record will persist, in all its mechanical glory.

Visual documentation does not depend on expert mechanical engineers, ladders or climbing tools anymore. Drones can help rapidly inspect and document the status of large vehicles like locomotives, while manual drones struggle to capture imagery up close or in overhung environments.

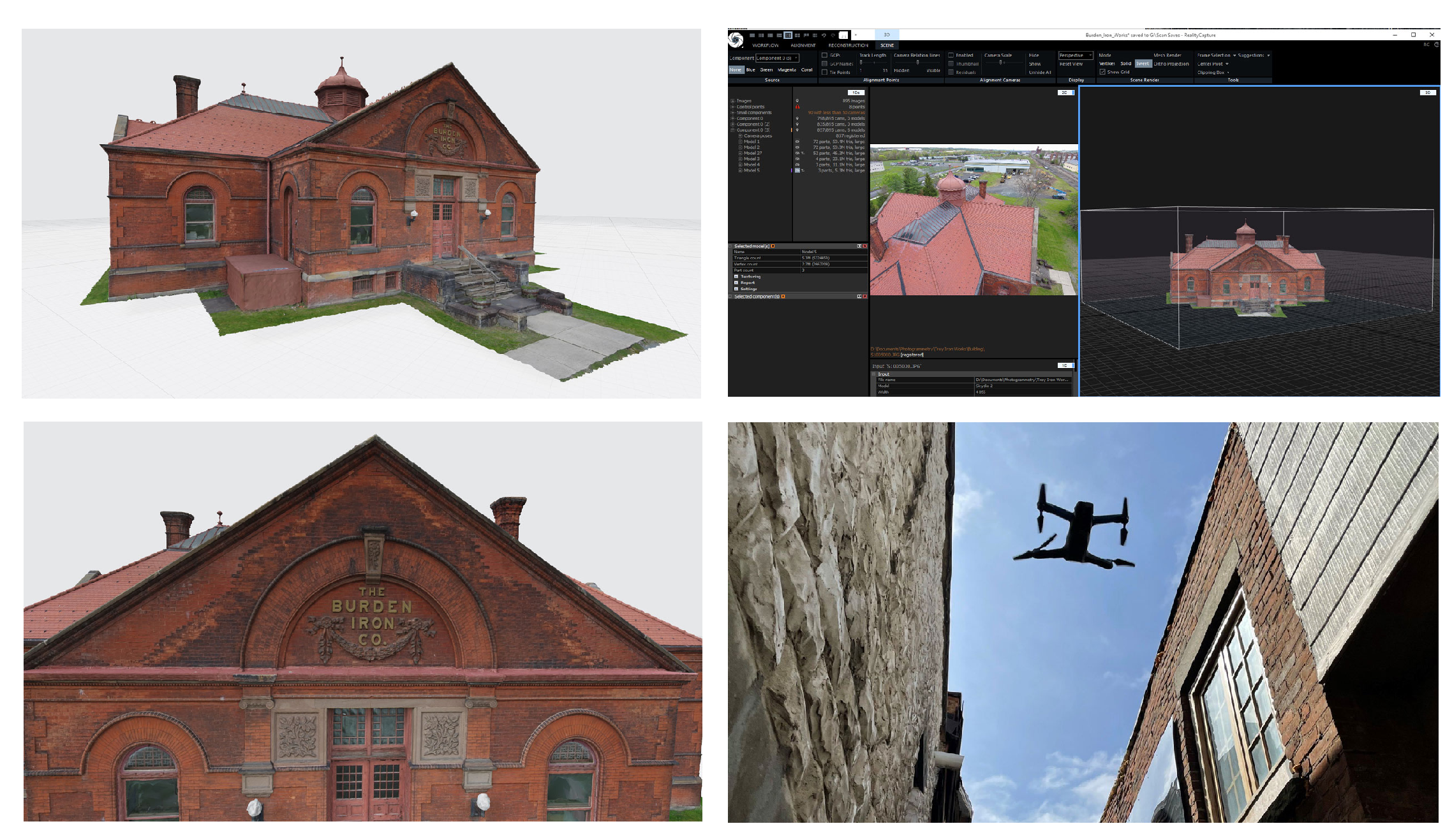

Last but not least, CapturingReality shared an incredible digital twin of Burden Iron works Museum, captured by Joseph Fazioli using a Skydio 2.

Burden Iron Works, built around 1880 as a one-story brick building laid out in a cruciform plan, is a museum inherited from the former administration building of the Burden horseshoe manufacturing empire. The Office building was listed on the National Register of Historic Places in 1972. It is a beautiful historical structure with clay roofing tiles, and interesting exterior features. Scanning this cultural heritage will not only preserve it in digital form but store an as-is documentation of a current state and plan for future restoration.

The world’s most efficient digital scanning

Here is how Skydio is different: Skydio 3D Scan is a first-of-its-kind adaptive scanning software to automate the data capture process needed to generate 3D models with comprehensive coverage and ultra-high resolution. It delivers higher quality inspections faster with minimal pilot training.

3D Scan is particularly ground-breaking relative to the manual drones today, which still present numerous challenges:

- Some scenes are impossible to scan. Manual GPS reliant drones cannot fly under/near obstacles (especially if they are made of concrete and/or metal), so they cannot capture complex scenes that require flight at low altitude. Since Skydio drones rely on vision and not GPS for navigation, these challenging environments are no problem for Skydio.

- Manual flight places the burden on pilots. Manual piloting takes up to 80% of the time needed to generate a 3D model, requires extreme pilot expertise, and can be dangerous to assets and teams on the ground. Pilot salary consumes over 80% of the average drone program’s budget, and extensive training requirements to safely operate manual drones can hamper drone fleets trying to grow their operations.

- Manual drones trade off safety for quality. Because manual drones are not reliable near the structures they are inspecting, they need to fly far away from the inspection asset, resulting in lower-resolution imagery unless investment is made in larger and more costly cameras, sensors and platforms. Flying up close to capture better data introduces greater collision risk, which again, is no problem for Skydio.

- Re-inspection rates reach up to 30% across the industry. Current inspection workflows require pilots to use rudimentary scripted flight patterns or take photos painstakingly by hand. In either case, there is no software-driven assurance that full data has been captured, and customers report having to re-inspect up to 30% of their jobs because when they get back, they realize they “missed a spot.”

- Stale data. Due to the difficulties listed above, even when more frequent inspections would be useful, they are not always performed, and the safety of society’s infrastructure suffers as a result.

3D Scan is already providing impact for customers, who are realizing tremendous value and impact. Check out our customer case studies with Accurate Drone Solutions, SUNDT, BostonPD and more .