Drone Autonomy For Bridge Inspection. The Newest Tool on the Inspector’s Belt.

Before drones came into the picture, inspecting bridges was an expensive and dangerous activity. Most commonly, the primary piece of equipment to inspect a bridge is a snooper truck, which is a large, expensive vehicle that takes a large crew to operate, and poses serious safety risks on the operators. In other cases, large bridges are even painstakingly inspected by workers rappelling on ropes from the top of the bridge.

Snooper trucks are expensive and dangerous

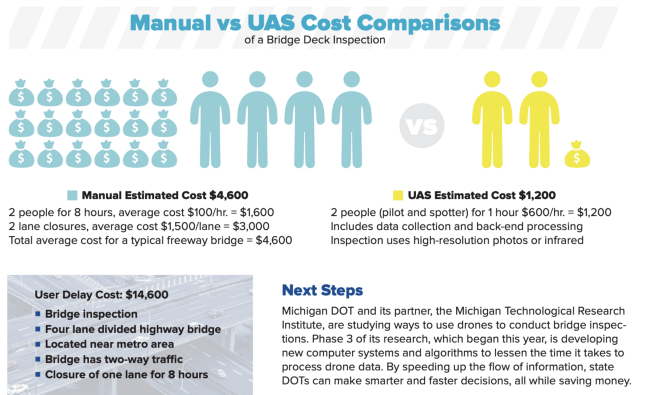

A recent study by the American Association of State Highway and Transportation Officials (AASHTO) found that the average cost to inspect a typical freeway bridge comes out to $4,600 using traditional deck inspection methods. The social costs to the users of the bridge are calculated to be $14,600 due to the disruption caused by extended lane closures. With such drastic cost disadvantages, it is no wonder that DOTs across America have been looking to drones as a replacement.

Drones are the clear solution to safe bridge inspection

While physical contact is occasionally required, our customers tell us that in most cases, a drone is a better way to give an inspector the vantage point he or she needs to assess whether a physical inspection or maintenance operation is truly necessary. Drones eliminate many of the pain points associated with snooper trucks and other legacy methods for bridge inspection. Drones are cheaper to buy (few thousand vs. 200k-500k for a truck), cheaper to operate (reduce cost per inspection by 75%), safer, non-intrusive to traffic, more environmentally friendly (no traffic jams)

What to look for in a drone for bridge inspections

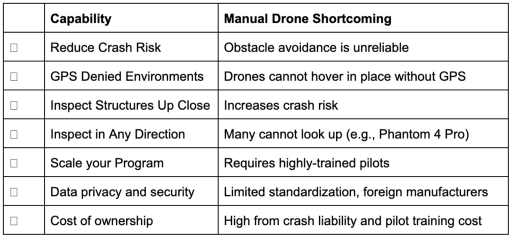

Despite these early adopters’ tenacity, programs have had trouble scaling because today’s manual drones are not conducive to equipping many pilots for many jobs. Manual drones carry several limitations for drone operators:

Manual drones don’t get the job done

Manual drones often crash

Any manual drone pilot can attest to the nervous, white-knuckle flight experience on a manual drone. Collisions are expensive, and the consequences of a collision can be severe enough to ground an entire drone program. YouTube is littered with unfortunate crash montages for DJI drones, yet to any enterprise drone operator, this is not a risk they can afford. Bridges are often over water (risks your drone) or roads (risks civilians below), and are a particularly bad environment for drones to fall out of the sky.

Fully dependent On GPS and magnetometers

Under a bridge, surrounded by metal trusses, the drone can depend on neither, and cannot hold its position without constant operator input. Combine that with the fact that the most common enterprise drones, the DJI Phantom and Matrice series, are fully dependent on GPS and Magnetometers, and the obstacle-rich, GPS-denied underside of a bridge is an extremely dangerous place to fly.

Manual drones can't get close enough for inspection

Because it’s so hard to keep a manual drone from crashing, inspection protocols with manual drones call for long stand-off distances to increase the pilot’s margin for error. This results in worse data, so teams have to pay more and more for increasingly expensive cameras in a fruitless quest to capture high-resolution imagery. As a result, DJI Matrice pilots invest tens of thousands of dollars in cameras like the $14,000 DJI Zenmuse XT2, which has the high resolution required to compensate for flying far away.

Most manual drones can't "look up", a crucial feature for bridge inspections

Most manual drones were not designed for enterprise-level applications, so they have a limited gimbal tilt. More specifically, they cannot look straight up to inspect the underbelly of bridges. The Mavic 2 Enterprise’s gimbal, for example, is mounted on the bottom, and has no way to look up. The DJI Matrice series forces operators to choose whether to mount their gimbal on top or bottom, or sacrifice battery life (and their budget) to mount two sensors at once.

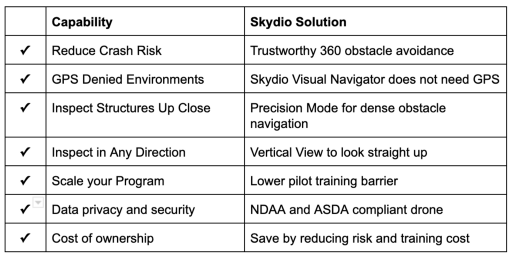

Skydio 2, autonomy and 3D Scan turn drones from niche tools to full-on industrial automation

Inspection is a major area of investment for our R&D. Many bridge inspectors and construction companies are already using Skydio 2 for their operations. From the Ohio and North Carolina Departments of Transportation, to Japan Infrastructure Waymark, our customers have found Skydio 2 to be a powerful new tool for inspectors.

As long as operators are constantly afraid to crash, drone programs will struggle to scale past early adopters. For everyday bridge inspectors to adopt drone technology en masse, drones will have to be as easy to use as cameras. That can only be true when the drone does the flying, so that — just like with a camera — all the operator has to do is point and shoot. Skydio drones are built from the ground up to accomplish this goal , with autonomy technology years ahead of any drone in their size class.

In the new category of Autonomous Drones, yesterday’s manual drone technologies just will not cut it. As you take the next step in developing your drone program, make sure that you are taking advantage of the benefits Skydio’s autonomy systems have to offer.

Autonomous drones are the path forward for automated bridge inspection

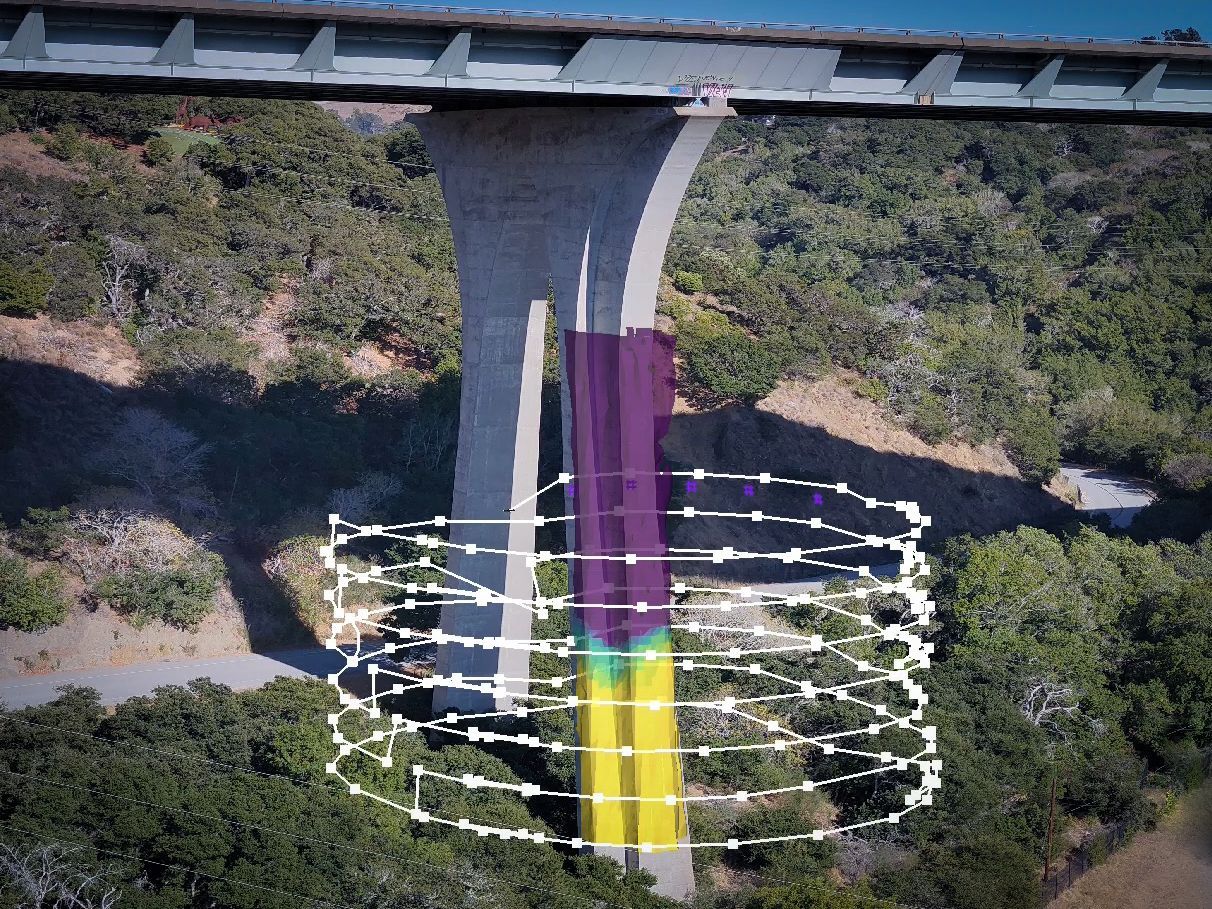

For drone operators looking to take their operations one step further, we have announced Skydio 3D Scan. Bridges are a notoriously hard challenge for 3D modeling, for a few reasons:

- It’s the bottom that matters. Today’s modeling software, such as Pix4Dcapture, is designed to script out a lawnmower-pattern flight from above the subject of interest. However, this isn’t much use for bridge inspectors, who often care more about the sides and bottom of the bridge.

- Bridges are hard to fully cover manually. Pilots need to make sure they have full coverage of overlapping photos for every surface of a bridge to generate a 3D model. On enormous bridges, this is nearly impossible to achieve, especially across multiple batteries. So, bridge inspectors take thousands of photos, which leads to hours of processing time to generate 3D models, and piles of full hard drives or cloud storage bills.

Skydio 3D Scan is different from today’s photogrammetry scripting solutions. Instead of giving the drone a series of waypoints to follow blindly, it equips your Skydio with a series of AI algorithms that can build a 3D model of a structure in real-time, and navigate around them to generate even photo coverage across every surface.

The result is the most efficient possible photogrammetry capture flight, with a smooth distribution of photos at the operator’s specified ground sampling distance. No white-knuckle flying. No “did I get that part?” No mountain of data. Just efficient, safe flight.

Skydio’s 3D scan technology has been released. Learn more about it and how it can improve your bridge inspection process by visiting the 3D Scan Technology page.