Scaling Cell Tower Inspections With 3D Tower Capture

From post-construction audits to annual inspections and acquisition assessments, drones and digital twins in the telecom industry are not new concepts. Drone cell tower inspections have emerged as a clear solution, improving safety and generating higher-quality data. Still, capture methods with manual drones have struggled to scale with the industry's growth, requiring expert pilots to spend endless hours programming waypoint missions on a site-by-site basis.

Leveraging the power of AI-enabled autonomous drones addresses this scalability issue, significantly simplifying complex flight planning and data capture processes that often plague manual drones. The data can then be used to generate 3D models, one of the most prevalent outputs in the telecommunications industry that unlocks massive value, giving cell tower operators and other key stakeholders the ability to visualize a tower model in three dimensions.

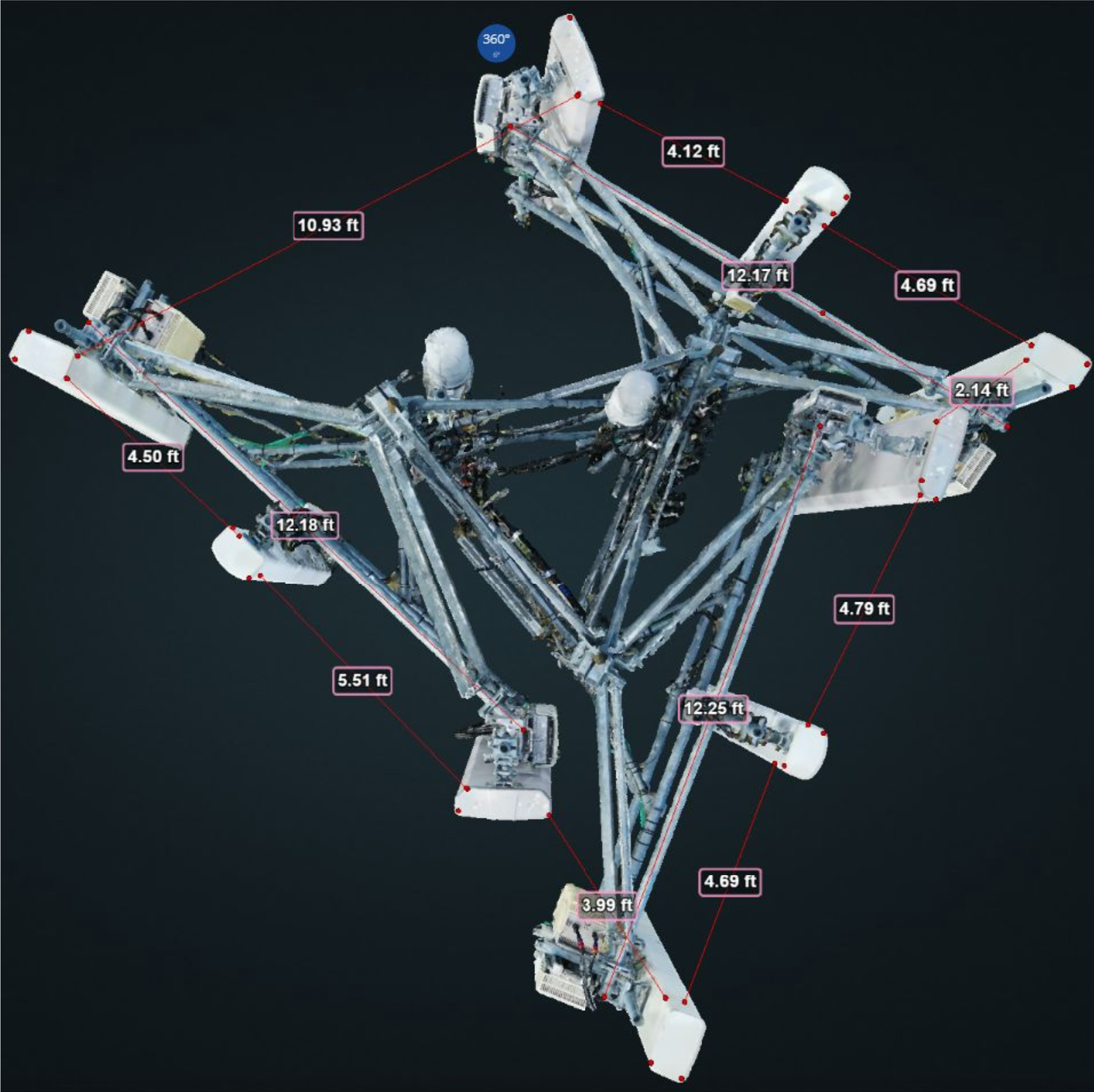

Traditional methods of telecom inspection involve dangerous climbs, inefficient collection methods, and often ineffective datasets that fail to capture the complete set of details. Digital twins are the future of tower inspections. They provide accurate models of the real world that can easily be shared between stakeholders to help manage and maintain an accurate record of each tower. Interacting with this model captured with 3D Tower Capture – a new capture mode of Skydio 3D Scan that is optimized for towers and other tall structures – emphasizes the true intelligence of digital reconstruction. This detailed model is extremely useful for inspecting telecom assets and managing inventory.

- Site Inspection - Telecommunication towers, like many other outdoor structures, are prone to damage from aging and normal wear and tear. This is especially true for towers located in regions that experience severe inclement weather. Regular site inspections enable tower operators with accurate, up-to-date structural data of a tower and its surroundings they can use to schedule routine maintenance and extend the service life of the tower.

- Post-Installation Inspection - Data captured at the time of installation can be used to generate a model to provide proof of proper installation and structural integrity to the owner before the project’s close-out or final acceptance. Visual inspections via climbs put employees at risk, and manual drone inspections struggle to capture the best possible data set to inform accurate decisions.

- Asset & Inventory Management - Maintaining a repository of digital twins can help large organizations with distributed assets keep better track of their towers to inform procurement, planning, forecasting, and network optimization decisions. With a digital twin, historical data and a full 3D reconstruction of the tower are readily available and shareable.

3D tower capture: Powering autonomous tower scans at scale

In February of this year, we introduced 3D Tower Capture, the latest autonomous capture mode of Skydio 3D Scan optimized for vertical structures. At a time when the telecom industry is experiencing explosive growth, with nearly a 4,000% increase in average data consumption per capita in North America between 2010 and 2020, tower owners, carriers, and vendors are being pushed to their inspection capability limits. Drones have emerged as a clear solution, but data capture with manual drones has struggled to scale with the industry's growth. Couple inefficient inspection methods and manual drone processes with the hundreds of thousands of towers that need to be inspected annually, and the issue of scalability quickly presents itself. Enter 3D Tower Capture.

Plan flights efficiently

The world is three-dimensional, and the data organizations use to make decisions about their assets should be too. 3D Tower Capture leverages 3D Scan’s capture technology with improvements to simplify inspections of vertical structures. Rather than setting up complex, time-consuming waypoint-based inspections with manual drones, 3D Tower Capture allows you to define the scan volume as a cylinder through four simple parameters: Floor, Ceiling, Center, and Radius.

Simplify data capture

Compared with other forms of critical infrastructure like bridges and railways, a telecom tower presents a structure far more standardized in shape, warranting a simpler capture flight plan. 3D Tower Capture optimizes the scan’s flight plan by defaulting its flight path to begin at the top or bottom of the tower, adaptively planning an optimal spiral flight path consistently offset from the structure's surface at the predefined distance. This simplified data collection method reduces the number of images captured, in turn dramatically decreasing the total time spent scanning no matter how many RAD centers are on the tower, where they're located, or the type of tower.

Leveraging the spiral flight path creates additional opportunities to be even more efficient. In instances of larger multi-battery scans, 3D Tower Capture adjusts to start at the top of the tower rather than the bottom, saving time because the drone has a shorter distance to fly when repositioning itself after each battery swap.

Process data reliably

Visual imagery provides value to tower operators through the ability to select an image and analyze it at a granular level, for instance, selecting a particular image to read a serial number. However, far greater value can be derived from telecom tower inspections leveraging the imagery in the form of 3D models.

We’ve built 3D Tower Capture to default the camera gimbal angle to face downward, ensuring the images only contain important textured surfaces while avoiding capturing textureless blue sky that often impacts model accuracy. The sharp look-down angle of 3D Tower Capture also increases ground capture, which helps anchor the model to global coordinates and enhance model accuracy, especially when using ground control points.

Nevertheless, 3D models aren't always the desired output and there are use cases where it may be essential to capture images looking up. As a result, Skydio built 3D Tower Scan with flexibility in mind. For example, if upward-looking images are desired to evaluate bottom attachment points on critical components, an operator can easily adjust their settings in 3D Tower Capture to ensure that every angle is captured.

Creating an end-to-end inspection workflow

Like all other capture modes in Skydio 3D Scan, 3D Tower Capture enables users to export all images captured during a scan with full metadata to any third-party photogrammetry software to create 3D models. We actively partner with companies like Bentley, DroneDeploy, Pix4D, and RealityCapture to optimize our output for their platforms.

While data capture is an essential part of the inspection process; enterprises need to be able to derive analysis and make decisions from the data. With this in mind, Skydio partners with tools like Optelos’ data management platform.

Companies performing asset inspections can aggregate and organize data, visualize models, and rapidly identify issues with analysis tools to determine azimuth and downtilt, generate accurate measurements, and compare 3D models to CAD design documents that turn inspection data into actionable insights. Further enabling enterprises to leverage data in the form of 3D models and PDF reports to streamline decision-making, increase inspection volume, and improve ROI.

To learn more about Skydio’s solutions for the telecom industry, download Volume 5 of the Enterprise Drone Inspection Ebook focused on the telecom industry. If you want to speak with an expert from our team or schedule a demo to learn more about 3D Tower Capture and cell tower drone inspections, click below to contact us.