The traditional approach to maintenance has long been a predictable, calendar-based routine. Like setting a reminder to change the oil in your car every six months, utilities have scheduled inspections and repairs based on time intervals.

This method, while straightforward, often overlooks the actual condition of the equipment, leading to two main pitfalls: over-maintenance, where resources are spent on assets that don't yet need attention, and unexpected failures, where issues go unchecked until they cause breakdowns.

Enter condition-based maintenance (CBM), a transformative strategy that promises to revolutionize how utilities operate. By focusing on the real-time health of assets rather than the calendar, CBM aims to increase efficiency, reduce costly downtime due to equipment failure, and boost the lifespan and reliability of vital infrastructure. This shift from a reactive to a proactive stance is not merely an operational upgrade; it's a strategic evolution critical for the future of utility maintenance.

Understanding condition-based maintenance

Imagine driving your car with a system that constantly monitors every component's health, from the engine's performance to the wear on the brake pads. Instead of visiting the mechanic based on a fixed number of miles driven, you're alerted to specific issues as they arise, ensuring timely maintenance that keeps your car running smoothly without unnecessary visits to the shop. This is the essence of CBM.

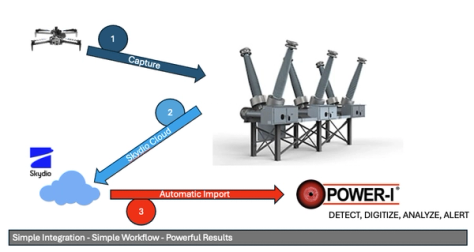

In the utility sector, CBM leverages the latest advancements in technology, such as drones equipped with sophisticated sensors and artificial intelligence (AI), to monitor the condition of infrastructure in real-time. These tools provide a detailed view of assets, from transmission lines to substations, capturing data that was previously inaccessible or difficult to obtain. By analyzing this data, both in the moment and over time, utilities can predict potential failures before they happen, scheduling maintenance only when and where it's needed, and gaining the ability to prioritize with data-driven decisions.

This proactive approach allows for a more accurate, efficient, and safer way to manage utility assets. With CBM, the goal is to maximize the health and longevity of the infrastructure, ensuring a stable and reliable supply of essential services to communities around the globe.

Benefits of condition-based maintenance

1. Reduced costs and increased efficiency

CBM eliminates unnecessary maintenance, ensuring that work is performed only when needed. This not only reduces operational costs but also minimizes downtime and disruptions to service.

2. Extended asset life

By identifying and addressing maintenance needs based on actual conditions, CBM can prevent premature wear and tear and extend the lifespan of utility assets.

3. Enhanced safety and reliability

Early identification and mitigation of potential issues enhance the overall safety and reliability of utility infrastructures, contributing to a more stable and secure energy supply.

4. Improved decision-making

With CBM, utilities gain access to comprehensive and accurate data on asset health, supporting informed decision-making and strategic planning.

Challenges and the path forward

Despite its advantages, transitioning to CBM is not without challenges. These include overcoming resistance to change, managing the technical complexity of integrating new technologies, and addressing budget constraints. However, by developing a comprehensive strategy that includes assessing organizational readiness, conducting cost analysis informed by current maintenance practices, and implementing pilot programs, utilities can navigate these challenges and prove solution ROI on day-one.

Drone technology in utilities

The role of autonomous drone technology in this transformation is pivotal. Cutting-edge utility asset monitoring solutions designed with a deep understanding of the sector's needs, are helping utilities worldwide navigate the path to condition-based maintenance. By providing reliable, efficient, and safe inspection solutions, vendors like Skydio are not just drone technology providers but strategic partners in the utility sector's journey towards a more sustainable, reliable, and efficient future.

Multiply workforce output

Knowledge experts are nearing retirement and utilities are searching for the next generation of utility workers. AI-powered drone solutions are well suited to not only multiply the output of workers stepping into new roles, but also to usher in the next generation of technology-interested professionals to the utility industry.

Skydio utility solutions are specifically designed to meet the needs of organizations at every stage of drone technology implementation. Whether operated by pilots, frontline staff, remote pilots, or autonomously via drone docking stations, organizations are multiplying their organizational output with data-backed decision-making. The capabilities of Skydio X10, are defined by it’s software, enabling a regular cadence of feature enhancements, improvements, and partner API integrations.

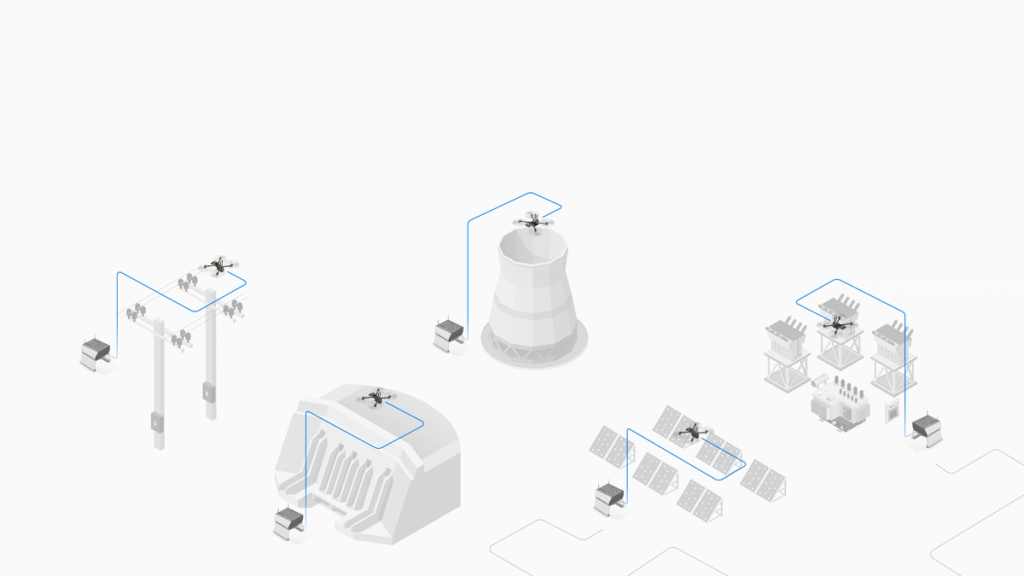

Automated asset monitoring system

Fully automated drone docks, represents a significant opportunity for enhancing utility asset management strategies. Docks enable drones to operate remotely, launching, landing, and charging without human intervention. This autonomy transforms how utilities conduct inspections and monitor asset health, providing a plethora of benefits that align with the goals of condition-based maintenance.

Value Proposition and Benefits

1. Continuous, Real-Time Monitoring

Drone docks facilitate continuous and real-time monitoring of utility assets. This capability ensures that utilities can promptly detect and address issues, preventing minor problems from escalating into major failures.

2. Increased Operational Efficiency

By automating the drone operation process, utilities can choose to reallocate workforce resources where they will be most impactful, or enable them with new tools to enhance their output. Resulting in more frequent inspections with fewer resources.

3. Enhanced Safety

The use of drones for inspections minimizes the need for human workers to enter hazardous areas or perform risky maneuvers. This reduction in direct human involvement enhances worker safety and compliance with health and safety regulations.

4. Scalable and Flexible Solutions

AI-powered drones are designed to scale with the needs of utilities. Whether addressing emergent issues or conducting routine inspections, drones can be deployed quickly and adapted to various operational requirements.

5. Data-Driven Decision Making

The integration of AI and advanced analytics with drone-captured data provides utilities with deep insights into asset health. This rich data supports more informed, strategic decision-making and paves the way for a more proactive maintenance approach.

Paving the Way for Advanced CBM Strategies

The advancements in AI and drone technology have opened new avenues for utilities to enhance their maintenance strategies. Progressive organizations are leveraging these technologies to integrate AI-powered data-capture and analysis solutions. Such solutions not only streamline the inspection and monitoring processes but also enrich the quality and accessibility of data on asset health.

This trend towards integrating AI with drone operations is enabling utilities to multiply their workforce and organizational output, particularly in strategic decision-making and complex asset management. The ability to gather comprehensive, accurate data without increasing headcount or operational costs is transforming the utility sector, making CBM strategies more effective and achievable.

Real-world impact

- Pacific Gas and Electric Co. (PG&E) became the first utility company in California to use remotely operated drones. PG&E's remote drone program is focused on reliability and efficiency, utilizing drones to examine the equipment and quickly identify issues.

- Southern Company has obtained an FAA waiver allowing for drone inspections at its facilities without onsite personnel, enhancing efficiency and safety by enabling remote inspections from a control center and reducing the need for dangerous on-site evaluations.

- American Electric Power (AEP) has demonstrated the value of drones in initial damage assessments, uncovering an imminent failure that could have led to significant downtime and costs. This proactive identification of issues underscores the potential of drones to enhance grid resilience.

- ComEd Secured waivers from the FAA to conduct beyond visual line of sight (BVLOS) from drone docks, enabling safe, cost-effective on-site and on-demand surveillance capabilities, supporting grid performance, and proactive problem identification to prevent power outages.

- Dominion Energy uses drones across its operations for electric transmission operations, power generation inspections, and supporting operations at solar farms and construction sites.

- New York Power Authority (NYPA): Approved the first phase of funding for a $37.2 million drone program aimed at improving safety, and efficiency, and advancing NYPA’s role in leading efforts to realize New York’s clean energy future.

Shaping the Future of Utility Maintenance

Skydio provides fully integrated, remotely operated, and/or fully automated end-to-end solutions for monitoring asset health. By harnessing the latest trends in AI and drone technology, Skydio is not just providing utilities with a tool for data capture but is offering a comprehensive platform for enhanced decision-making and strategic asset management. As utilities continue to embrace these technological advancements, Skydio stands ready to support them in maximizing their potential, ensuring a future where maintenance is predictive, efficient, and safety-focused.

Learn more about Skydio drones for utility asset inspection and monitoring.

About the author

Christina Park is a seasoned veteran in the energy and utilities sector, focusing on how technology can improve infrastructure maintenance and sustainability. With multiple degrees in Mechanical Engineering and 20 years of experience, she brings a mix of technical knowledge and strategic insight to her work.

Her interest lies in operationalizing technology to optimize maintenance practices. Christina advocates for data-driven decision-making to enhance utility operations' efficiency, reliability, and sustainability.

Christina is an active participant in energy sector associations, speaking at industry events and writing for publications like Energy Central. Her contributions aim to educate and inspire energy professionals to embrace technology and innovation for a more sustainable future.